How BIM Integration Enhances Infrastructure Design and Construction

Imagine having all the essential details about your building at your fingertips. From proactive design to maintenance schedules and all other necessary information.

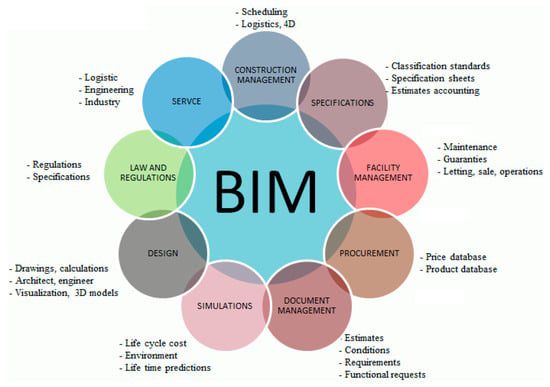

This imagination meets reality with the help of Building Information Modeling (BIM), which is used to create a digital representation of the basic characteristics for an infrastructure. It’s a collaborative process that involves architects, engineers and contractors working together to design a complete 3D model of a project.

The major aspect of BIM is its ability to quickly differentiate and integrate information by converting it into an accurate model. As a result, multiple stakeholders can work on a project simultaneously with less chances of errors.

This article will explore how BIM integration strengthens infrastructure design and construction.

image source: “https://microsolresources.com/”, alt: “AEC BIM”

Enhancing Collaboration Across All Project Phases

BIM enhances construction projects by allowing architects, engineers, contractors and other stakeholders to collaborate in a virtual system. Through BIM, we can create detailed 3D models of buildings and infrastructure along with the primary information related to each element. Therefore, it’s simply a virtual twin of the original structure.

BIM collaboration tools such as Autodesk, API and Navisworks can be integrated to enhance collaboration across all project phases, which include:

- Design phase

- Pre-construction phase

- Construction phase

- Operation and maintenance phase

image source: “Image created in-house”, alt: “Four stages of the BIM process”

During the design phase, the architect develops models that are reviewed by the contractors and engineers to reduce the risk of future errors.

This review process is also known as the pre-construction phase, where stakeholders reach an agreement in the common data environment (CDE) to optimize project execution.

In traditional construction, errors and miscommunications can lead to an expensive modification. However, with BIM collaboration, potential clashes between building blocks are detected and corrected in the pre-construction phase.

Therefore, the accuracy of the construction phase is determined by the evaluations and geotechnical tests conducted during the first two phases of the BIM process.

Boosting Efficiency and Cost Management Through Integrated BIM Processes

BIM is usually integrated with various software tools to improve construction efficiency and keep stakeholders informed with real-time updates. Examples of these tools include:

- eSUB

- Smartsheet

- Basecamp

- PlanGrid

- Microsoft Azure

To seamlessly integrate these tools with BIM, construction workers use either direct file import or application programming interface (API) connection. Keep in mind that the latter is more preferred because it saves more time than the former.

A key feature of BIM is its advancement system that allows architects to create both 3D and 4D models for building projects. This means that when a 3D design is created in the BIM, the software can easily update the model to 4D at a low cost without deleting the original design.

image source: “https://www.freepik.com/” alt: “BIM augmented reality”

Furthermore, BIM tools can easily identify incompatibility between different building systems, such as electrical, plumbing and HVAC systems before construction begins. This helps the building workers to reduce unnecessary stress and costly rework.

Based on the NBS National BIM report, more than 70 percent of construction workers state that BIM improves project efficiency, cost management and project delivery. In addition, BIM tools can also be used to reduce waste and improve procurement accuracy, which prevents stakeholders from running short on supplies during the building process.

Minimizing Errors with Proactive Design Integration

According to a recent report from ResearchGate.net, lack of knowledge and information is the main reason for design errors. Therefore, BIM tools are proactively designed with informative clash detection and parametric modeling features that are used for reducing errors in building projects.

The clash detection feature identifies potential errors before construction begins, while the parametric modeling feature is specifically used for confirming design accuracy during the building process.

BIM software such as 3D Repo also helps stakeholders to minimize errors in the project initiation phase. It simply suggests designs that can prevent pipes, doors, beams and other building elements from colliding with one another. This proactive design integration strategy is called model-based design.

Another building approach that can mitigate errors with proactive design is the design-build strategy. In this approach, a single construction firm provides all the required building services, leading to better risk management and faster project delivery process.

image source: “https://www.freepik.com/”, alt: “prototype for design-build strategy”

The Role of Digital Twins in Shaping Future Infrastructure

A digital twin is a virtual representation of an infrastructure project created by using relevant information from the design, pre-construction and construction phase. It’s primarily used to analyze the performance of a building infrastructure and also to optimize construction.

Digital twins can be created by combining data from different sources such as BIM, building surveys and mobile mapping. The major roles of digital twins in shaping future infrastructure include:

- Planning and management of building operations

- Evaluation and validation of designs

- Enhanced collaboration among different stakeholders

- Technical simulation and asset management

Image source: “https://www.freepik.com/”, alt: “digital twins in construction”

The most affordable way to integrate digital twins in construction is through scanning and photogrammetry. You can also use a UAV drone to create a point cloud or 3D mesh model.

In addition, technology hardware such as lidar and 3D scanners can be used to capture the physical environment and establish a digital twin of a building or factory.

About Anna Montenegro

Anna Liza Montenegro develops design technology conferences for architecture, engineering and construction (AEC) professionals as a forum to exchange innovative strategies and best practices as well as facilitate discussions into the technology trends driving significant change in building design and construction. As director of marketing and as a trained architect, these events are offered to AEC professionals by Microsol Resources, a value-added reseller of Autodesk, Bluebeam, Enscape, Rhino, V-Ray, CADLearning, and other various technology partnerships; email: amontenegro@microsolresources.com.