Avoid Catastrophic Collapse, Protect Column Bases with Denso Covercoat Today

By: Eric Stark, Technical Director at Denso, Inc.

Protecting steel and concrete column bases from corrosion is crucial for maintaining the structural integrity and longevity of buildings and infrastructures. Corrosion is a significant issue, especially where steel columns and bolts connect to concrete bases.

Moisture, chemical and water infiltration at the column base surfaces create ideal conditions for rust to form, accelerating the deterioration of the steel and compromising its strength. Implementing effective protective measures is vital to prevent costly repairs, enhance safety, and extend the lifespan of the structure.

This challenge is especially pronounced in coastal areas and industries such as mining or heavy manufacturing, where airborne salts and chemicals accelerate the corrosion process.

Repairing or replacing corroded steel infrastructure is not only expensive but also causes substantial downtime. To avoid these disruptions, proactive corrosion prevention is critical. Taking preventative steps now is the most effective way to safeguard assets, minimize risks, and ensure long-term performance.

Advanced Corrosion Protection

Corrosion protection plays a vital role in safeguarding metal and concrete structures and components from deterioration, helping to ensure safety, reliability, and long-term asset performance. Effective protection not only extends the service life of assets but also reduces maintenance costs, prevents environmental hazards, and supports operational safety. The Denso Covercoat Column Base Protection System offers a durable encasement system with a proven solution to combat corrosion. Developed by Denso, a global leader with over 95 years experience in corrosion prevention and sealing technologies, the system is specifically designed to halt existing corrosion and prevent future damage of column bases.

The system is petrolatum-based, creating a protective barrier that prevents moisture, water, salts, and corrosive chemicals from coming into contact with any steel substrates. By blocking these corrosive elements, the petrolatum barrier helps ensure the steel remains protected throughout its service life.

In addition to the petrolatum coating, the system includes a durable outer shell that encases and physically protects the petrolatum-based products and sheds water from the concrete base. Together, these components offer comprehensive protection, ensuring the structural integrity of steel columns while minimizing maintenance costs and downtime.

Why Corrosion Happens

Corrosion is a natural process where metals, like steel, react with their environment, leading to rust (iron oxide). It occurs when water and oxygen contact the metal surface, creating electrochemical cells.

Water enables ion movement, while oxygen drives the reaction that breaks down the metal. Salt and other electrolytes accelerate the process by increasing water’s conductivity and breaking down protective oxide layers, particularly in coastal or polluted areas and in mining and chemical processing operations.

Rust also expands, occupying a larger volume than the original metal. This type of expansion causes cracking and spalling within concrete pilings.

Preventing corrosion involves disrupting the reaction. Protective coatings, like paints and galvanization (zinc coating) can help but can easily break down over time or be damaged easily due to impacts exposing the columns surface. Using corrosion-resistant materials, like stainless steel, is usually cost-prohibitive for large industrial structures. Denso’s CoverCoat system is a petrolatum barrier that can withstand impacts, shifting, and temperature changes to provide a comprehensive encasement system against corrosion.

A Proven Solution: Petrolatum-Based Coatings

Industrial petrolatum, a soft, wax-like substance derived from petroleum, is a highly versatile, non-toxic and safe material commonly used in various industrial applications. Denso Hi-Tack Primer, part of the Covercoat Column Base Protection System, is specially formulated with added adhesive properties to work seamlessly with Denso petrolatum tapes.

Unlike consumer-grade petroleum jelly, this industrial-grade product is designed for specific uses, such as corrosion prevention and enhanced tape adhesion. Its unique properties include a high melting point and resistance to harsh environmental conditions, making it ideal for demanding applications.

Denso’s Petrolatum Tape Systems for corrosion prevention have been used successfully in a variety of challenging environments, from tropical climates to arctic conditions, and in applications ranging from pipelines and valves to structural steel and tank bases.

Benefits of Petrolatum for Corrosion Prevention

Petrolatum-based solutions offer numerous advantages when it comes to preventing corrosion. They are highly cost-effective and provide outstanding long-term durability, significantly outperforming the alternative methods.

With a safe, simple, and eco-friendly application process free of harmful VOCs, these solutions also ensure the safety of both workers and the environment.

In contrast, liquid coatings often require extensive surface preparation, offer limited durability, and need frequent reapplication—leading to higher maintenance costs over time. Petrolatum stands out as a more efficient and sustainable option for protecting against corrosion.

Abrasive blasting, while effective, is time-consuming and requires significant resources for containment and cleanup. The process can remove existing rust, but on its own, it does not provide protection against future corrosion.

The petrolatum system, by contrast, offers a practical, easy, long lasting alternative. It requires minimal surface preparation and can be applied without disrupting nearby operations, eliminating the need for enclosures or specialized equipment often required by abrasive techniques.

A Simple Two-Stage Process for Steel Corrosion Protection

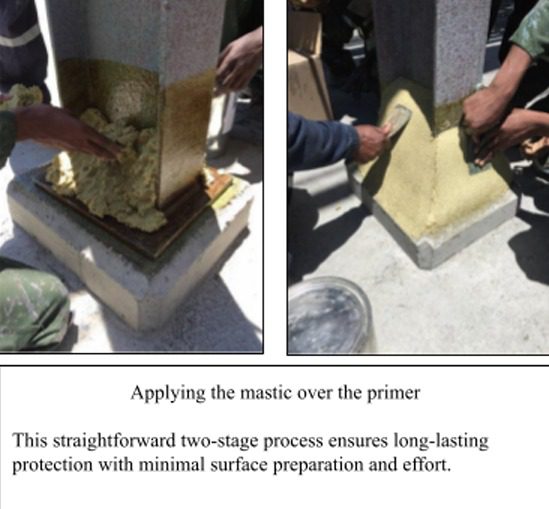

Protecting steel from corrosion doesn’t have to be complicated. The Covercoat Column Base Protection System includes all the materials necessary. This straightforward two-stage process ensures long-lasting protection with minimal surface preparation and effort. By combining petrolatum-based products with a durable hard shell, the system provides complete protection against water, oxygen, salt, chemicals, and physical damage. Here’s how it works:

Stage 1: Protecting the Steel with Petrolatum

This stage focuses on applying petrolatum-based products to shield the steel surface from water, oxygen, salt, and chemicals. Minimal surface preparation is required, making the process fast and efficient.

Step 1: Apply the petrolatum primer. Begin by preparing the surface using hand tools to remove any loose substances. Apply a thin layer of Denso Hi-Tack Primer to all steel surfaces that need protection. This specially formulated petrolatum primer has a high melting point petrolatum with added adhesive properties. The primer is very tacky and aids adhesion of petrolatum tapes.

Step 2: Apply profiling mastic. Denso Profiling Mastic is a cold-applied, self-supporting molding mastic. It is a petrolatum compound containing beads of closed cell cellular polymer and flow control additives. The profiling mastic fills holes, covers irregularities (like bolts), and creates a smooth fillet between the steel and the concrete base. The smooth profile and fillets prevent water and other contaminants from accumulating, reducing the risk of corrosion.

Step 3: Apply petrolatum tape. Finally, wrap petrolatum tape over the fillet and steel surface, ensuring each strip overlaps the previous one. Denso Hi-Tack Tape is composed of a non-woven synthetic fabric impregnated and coated with an adhesive compound based on petrolatum, polymers and inert siliceous fillers. This specially developed tape has exceptionally high adhesion qualities to protect irregular surfaces or where additional adhesion is required. The tape creates an airtight barrier, blocking oxygen from reaching the steel and preventing corrosion cells from forming.

This completes the petrolatum-based protection.

Stage 2: Protecting the Petrolatum with a Hard Shell

This stage builds a durable, water-shedding shell over the petrolatum products to protect them from the environment and ensure long-term performance. The hard shell is shaped to shed water from the concrete base, and the hard surface protects the column base from impact, and provides resistance against chemical and UV damage.

Step 1: Apply Denso D14 Scrim fabric. Apply one single layer by Laying strips of scrim fabric over the petrolatum-covered surface, trimming and shaping them to fit the area. Denso D14 Scrim is a non-woven fabric with longitudinal reinforcing stitching, manufactured from 100% polyester fibers. The scrim fabric is used as a reinforcement when saturated with the Basecoat in the next step.

Step 2: Apply Denso Basecoat coating. The Denso Basecoat Kit™ is a two-component durable coating, consisting of a liquid portion containing synthetic polymers and waterproofing admixtures and a cementitious powder portion consisting of fine fillers. Mix the two components of the Basecoat coating thoroughly. Dip the scrim fabric strips into the coating and reapply them to the surface. Once all strips are in place, apply an additional layer of Basecoat. Allow it to cure for 12 hours before applying the topcoat.

Step 3: Apply Archco 15, a UV-protective coating. After the Basecoat has cured, apply an acrylic UV-protective coating to the exterior surface and allow it to dry. Archco 15 is a single part, high build, flexible water based acrylic topcoat developed for Denso Tape Systems.

This shell creates a hard, durable enclosure that protects the petrolatum layer from physical, chemical, and UV damage while shedding water from the concrete base.

Protect Columns with the Covercoat System

The Covercoat Column Base Protection System offers a durable, two-stage solution that stops corrosion at the base of steel columns sitting on concrete. Designed for minimal prep and maintenance, it delivers long-lasting performance with minimal operational impact. Cost-effective and easy to apply, the system ensures reliable protection while being safe for both workers and the environment. It’s the smart choice for mitigating corrosion challenges.

Ensuring Long-Term Structural Integrity with Denso’s Advanced Protection

Implementing effective corrosion protection strategies is essential not only for safeguarding structural integrity and public safety, but also for minimizing environmental risks and reducing long-term maintenance expenses. Among these strategies, protective coatings, such as petrolatum-based systems, are widely used as a first line of defense, providing a physical barrier that shields metal from corrosive elements and prolongs service life. Regular inspection, timely maintenance, and the use of proven protection systems remain best practices for ensuring the durability and reliability of steel infrastructure across a wide range of environments.

However, corrosion at steel and concrete column bases continues to pose a persistent threat to the safety, longevity, and reliability of critical infrastructure. As a result, proactive corrosion protection has become increasingly recognized as a key strategy for extending infrastructure lifespan, reducing maintenance costs, and ensuring compliance with safety and environmental regulations. Traditional protective methods often fall short, especially in challenging environments where moisture, salts, and chemicals accelerate deterioration. In response to these challenges, the Denso Covercoat Column Base Protection System stands out by offering a proven, two-stage solution that not only halts active corrosion but also prevents future damage, all with minimal surface preparation and operational disruption.

Denso’s system leverages decades of expertise and innovation in corrosion prevention, combining the unique benefits of petrolatum-based coatings with a robust, water-shedding hard shell. This approach ensures comprehensive protection against water, oxygen, salts, and physical impacts, while also providing UV and chemical resistance. The result is a long-lasting, cost-effective solution that reduces maintenance needs and extends the life of steel structures.

With a track record of success in diverse industries and harsh environments, Denso’s Covercoat System is trusted by engineers and facility managers worldwide. Its ease of application, environmental safety, and ability to encapsulate even lead-based paints make it an ideal choice for both new construction and retrofit projects. By choosing Denso, stakeholders can be confident they are investing in a solution backed by over 95 years of experience, ensuring that their assets remain protected, operational, and resilient for decades to come.