Engineering Continuity: The EOR’s Role in Structural Steel Solutions for Historic and Architecturally Complex Renovations

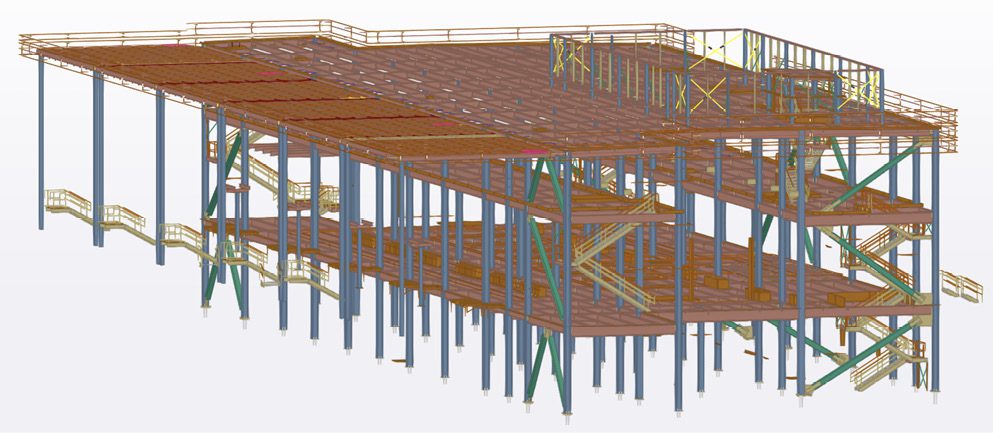

A 3D model of the Pepco Mt. Vernon substation in Washington, D.C. (Extreme Steel Inc.)

Historic renovations and architecturally ambitious retrofits walk a fine line between preservation and modernization. Whether it’s an adaptive reuse of a century-old mill or a new cultural landmark embedded in a dense urban grid, the challenges go far beyond aesthetics. Structural performance, code compliance, constructability and integration with existing materials all converge, requiring both technical precision and collaborative execution.

At the center of this complexity is the Engineer of Record (EOR). In projects involving structural steel, the EOR plays a pivotal role not only in design and documentation but also in ensuring that new steel elements are properly coordinated, fabricated and erected to meet both performance standards and preservation goals.

The EOR’s Expanding Role in Renovation Projects

In renovation, adaptive reuse and historically significant projects that involve structural steel, the EOR takes on a uniquely complex and consequential role. As the licensed professional responsible for the structural integrity of the building, the EOR’s duties span every stage of the project, from initial design through final inspection. Their expertise ensures that both modern performance standards and preservation priorities are met.

The process begins with structural design and documentation, where the EOR develops the building’s load-resisting framework and produces detailed drawings. These documents define how new or retrofitted steel components should function within the constraints of the existing structure, including specifications for beam sizing, connection geometry and tolerances.

Beyond structural design, the EOR ensures compliance with local codes and national safety standards, including the International Building Code (IBC), ASCE 7 for load criteria and in many cases, additional preservation guidelines that apply to historically protected buildings (iimag.link/TuYCd).

Successful execution also depends on the EOR’s ability to coordinate with the broader design and construction team. They work closely with architects, MEP engineers, steel fabricators and envelope consultants to verify that the structural solution is not only sound but also constructible, particularly when working with aging infrastructure or irregular building geometries that often accompany historic renovations.

As fabrication begins, the EOR is responsible for the review and approval of shop drawings, ensuring that the steel components reflect the original design intent and can be installed as planned. This includes verifying bolt hole patterns, weld callouts and connection details against field conditions and modeling data.

During construction, the EOR plays a hands-on role through site observation and real-time problem solving. When undocumented voids, misaligned framing or unanticipated conflicts arise, as they often do in renovation work, the EOR must quickly evaluate options and approve safe, effective adaptations to the structural solution.

Finally, the EOR provides support for permitting and inspections by signing and stamping structural documents and responding to inquiries from authorities having jurisdiction (AHJs). They also may engage in peer reviews, coordinate special inspections and serve as the technical authority through project closeout.

Taken together, these responsibilities position the EOR as a vital bridge among design vision, construction execution and regulatory oversight, particularly when structural steel is used to reinforce, adapt or elevate buildings that must stand up to both modern demands and the weight of history.

A Unique Role in Historic and Complex Renovations

Among all available building materials, structural steel offers a unique combination of strength, adaptability and precision that makes it especially well-suited to historic renovation and retrofit work. When updating older buildings, particularly those with spatial constraints or preservation requirements, steel’s properties enable design teams to reinforce and adapt existing structures without compromising their character.

Construction progress at the Pepco White Flint substation in Montgomery County, Maryland. (Extreme Steel Inc.)

One of the most important advantages is its high strength-to-weight ratio, which allows steel to provide substantial load-bearing capacity without adding unnecessary mass. This makes it an ideal choice for reinforcing aging floors, walls or roofs in buildings where heavier materials might exceed the limits of the original structure.

Steel also excels in customizability. Fabricators can shape and size steel components to match irregular geometries, which is especially useful in historic buildings where framing may be misaligned or inconsistent due to age or prior modifications. These capabilities make steel highly compatible with adaptive reuse strategies, allowing it to serve structural and spatial needs.

Another key benefit is efficiency in installation. Because steel elements are fabricated offsite in controlled environments, they can be delivered and erected quickly, reducing the amount of time spent onsite. This minimizes disruption to fragile finishes, historic interiors and nearby building occupants, an important factor when working within sensitive or active environments.

In terms of long-term performance, steel also offers excellent durability and fire resistance. It can be galvanized to resist corrosion, coated for added protection or treated for fire rating. These attributes help extend the life of structural systems while keeping maintenance requirements low.

Finally, steel contributes to preserving visual authenticity. When carefully integrated, structural elements often can be hidden behind original finishes or embedded within existing walls and ceilings. This allows upgrades to be made without visibly altering the character-defining features of the building, an approach endorsed by preservation guidelines such as those from the National Park Service (iimag.link/Nrqyt). Taken together, these attributes make structural steel not only a practical solution but a strategic asset in balancing the demands of safety, code compliance and architectural preservation.

Case in Point: AESS and the International Spy Museum

A compelling example of the coordination and technical precision required in complex steel projects can be found in the International Spy Museum in Washington, D.C. Although not a historic renovation in the traditional sense, the museum’s construction demanded many of the same skills and disciplines, particularly when it came to managing tight tolerances, intricate geometries and challenging site logistics in an urban setting.

The project centered around the installation of architecturally exposed structural steel (AESS), where the steel components were not only load-bearing but also highly visible design features. This dual role meant that each element served both a structural and aesthetic purpose, with exposed connections and finished surfaces subject to detailed review and approval from both the architect and the EOR.

Because the steel would remain visible in the final design, tolerances were especially strict. Even minor deviations could undermine the architectural intent, making close collaboration between the EOR, fabricator and erection crew essential throughout the process. Every beam, gusset and bolt had to be executed with precision.

Compounding these technical challenges was the museum’s congested urban location. With limited crane access and virtually no room for laydown or staging, the project team relied on phased deliveries and just-in-time installation to keep the schedule on track without overwhelming the site.

Though distinct from a preservation project, the Spy Museum illustrates how modern structural steel, especially when it is central to the visual identity of the building, requires a high level of coordination. It also underscores the EOR’s broader role in ensuring not only the structural safety of the system but also the fidelity of the finished design when the steel itself becomes a defining architectural element.

A photo shows the International Spy Museum in Washington, D.C., in construction. (Extreme Steel Inc.)

Best Practices from the EOR Perspective

When structural steel is used in historic renovations—whether reinforcing an 1890s civic building or retrofitting a 1930s industrial warehouse—certain best practices support both technical success and preservation goals.

1. Minimize Intervention with Precision

Steel allows for high-strength retrofits that leave original materials largely untouched. Interior moment frames or knife plates can be designed to reinforce historic masonry without altering the exterior. This is a preferred method for seismic or structural upgrades when visual impact must be minimized.

2. Rely on Laser Scanning and BIM

Today’s steel fabrication often starts with a 3D laser scan of the existing structure. The point cloud data is imported into building information modeling (BIM), allowing engineers and fabricators to model connections, shims and anchor points with extreme accuracy. This is especially valuable when aligning steel to historic floor levels, windows or pilasters that may not follow modern gridlines.

3. Preserve Envelope Continuity

The EOR must work closely with envelope consultants to ensure that structural steel integrations do not compromise moisture control, thermal insulation or air barriers. Knife plates can serve as anchor points for rainscreens or canopy systems, but thermal breaks, flashing and corrosion-resistant finishes must be detailed from the outset to prevent future envelope failure.

4. Plan for Limited Access

In retrofit settings, steel elements often need to be brought in through existing doorways or openings. Components may be spliced or assembled in tight spaces to avoid removing historic facades. This strategy is consistent with guidance from the National Park Service, which supports internal reinforcement techniques that minimize damage to character-defining features.

Engineering Respectfully for the Future

In historic renovations and architecturally ambitious projects alike, the EOR is the guiding hand that ensures structural performance while honoring design intent. Structural steel, when properly coordinated, detailed and installed, offers a powerful solution for balancing preservation with performance. From discrete retrofits that hide behind limestone cornices to exposed steel frames that define a building’s identity, steel’s adaptability makes it an indispensable material in the renovation toolbox.

Its success ultimately depends on the EOR’s leadership, translating design ambition into structural reality, protecting safety and preserving the legacy of the built environment, one beam, bolt and bracket at a time.

About Robert Pelham

Robert Pelham is the president and CEO of Extreme Steel Inc.; email: rPelham@extremesteelinc.com.