“Apollo”® v-port series control valve launched by Aalberts integrated piping systems

Control valve provides precise flow control to enhance the efficiency and performance of various systems

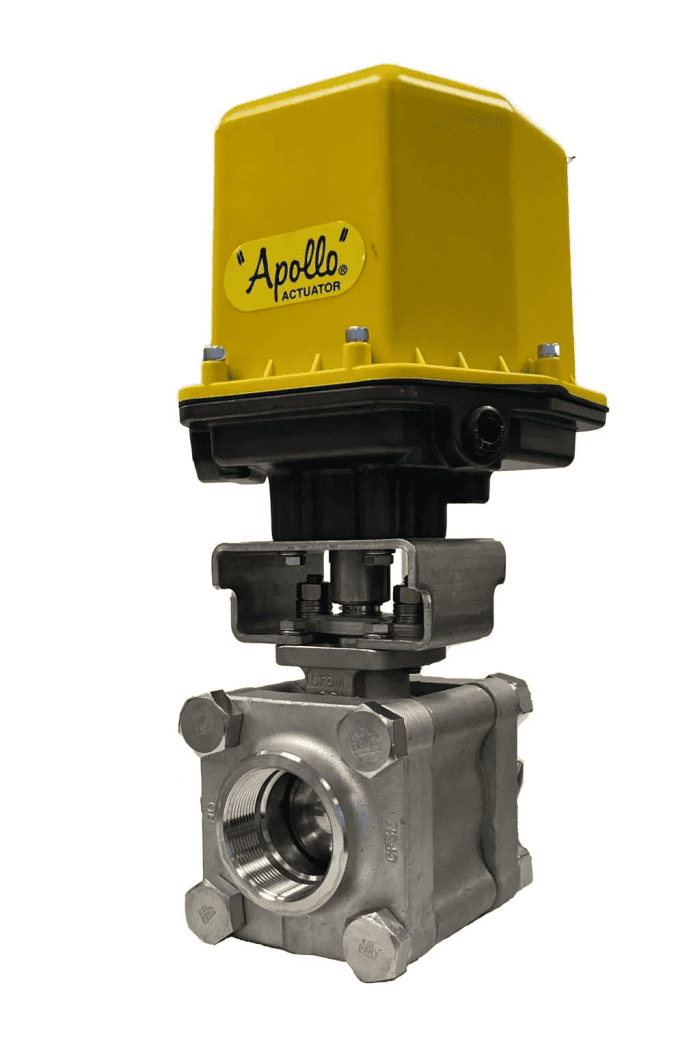

Aalberts integrated piping systems (IPS), a global leader in advanced integrated piping systems for the distribution and control of liquids and gasses, announces the launch of the innovative “Apollo”® v-port series control valve. This new control valve represents a significant advancement in the product lineup, offering a reliable and versatile solution for a variety of industries such as agriculture, power generation, renewable energy, chemical processing, oil, gas, petrochemical, food & beverage, biotechnology, pharmaceuticals, and municipal water treatment.

The “Apollo”® v-port series control valve is designed to offer precise flow control, enhancing the efficiency and performance of various systems. Whether managing aggressive chemicals, critical temperature control, or precise fluid distribution, this valve ensures optimal results and long-lasting performance even in the most demanding environments.

Incorporating advanced design features, the “Apollo”® v-port provides improved control over fluid dynamics, reducing operational costs and enhancing system performance. Additionally, it offers significant energy savings, contributing to cost-efficient operations.

Key features of the “Apollo”® v-port include a 3-piece construction with enclosed fasteners for easy maintenance and repair, standard port and full port options for versatility, and stainless steel trim and hardware for corrosion resistance. The pressure-balanced solid ball reduces operating torque and ensures smoother operation, while compression-controlled spiral wound gaskets improve sealing and reduce leakage. The anti-blowout one-piece bottom entry stem enhances safety by preventing stem ejection under pressure, and the statically grounded ball, stem, and body reduce the risk of static electricity buildup.

The valve features live-loaded stem packing, which maintains seal integrity and reduces maintenance frequency. It also includes adjustable graphite stem packing for in-situ adjustments and a fully machined ISO 5211 mounting pad for standardized actuator mounting. Additional features include fire safety compliance with API 607 standards, CE marking for adherence to European regulations, and a 250 psig saturated steam rating for high-temperature applications.

Crafted at Aalberts IPS’s facility in Conway, South Carolina, the “Apollo”® v-port exemplifies American manufacturing excellence. Aalberts IPS is committed to delivering top-tier customer support and responsive field services, ensuring smooth and efficient operations from installation to ongoing maintenance.

To learn more about the varying model options within the v-port series, visit https://www.youtube.com/watch?v=B52cx0Bj95M or contact our dedicated American-based team for personalized assistance. Embrace the future of industrial control with Aalberts IPS’s “Apollo”® v-port series control valve, designed for efficiency, sustainability, and superior performance.

About Aalberts IPS

Aalberts integrated piping systems (IPS) is a global leader in creating mission-critical valve and connection technology through its “Apollo”® brand with a legacy spanning over 95 years. The product profile includes ball valves, butterfly valves, safety relief valves, control valves, mixing valves, and backflow preventers, serving many industries such as residential, commercial, industrial, and utility markets. The company’s commitment to quality is evident in its proactive design and manufacturing processes, with a significant portion of production proudly conducted in the US. Connect with Aalberts IPS on LinkedIn, Facebook, and Instagram.