Digital Twins Add Value for Owners Across the Project Lifecycle

Reality-capture technology provides architects and design teams with increased accuracy at the start of a construction project.

When discussing the nation’s infrastructure and its need for revitalization, the conversation must focus on the role of technology, which has the power to revolutionize the country’s approach to infrastructure. Against this backdrop, federal agencies are increasingly turning to digital twin models on federally funded projects.

Civil and structural engineers must be prepared for federal agencies and state departments of transportation to start requiring digital twins on projects. The time to prepare isn’t after agencies require digital twins; it’s before. Unfortunately, many companies hold misperceptions about the true benefits of digital twins and don’t understand the extent of their power and how best to employ them on construction projects.

In the past, the construction industry relied on 2D datasets to create designs and plans. Relying solely on 2D datasets, especially outdated ones, can pose a significant risk to companies, such as making decisions based on inaccurate information, which could lead to costly or—in a worst-case scenario—deadly mistakes.

Crucial decisions require accurate information, and digital twins are a powerful tool contractors need in their arsenal. They give stakeholders the real-time details needed to inform their decisions. The resulting digital twin, when updated through time, will add value for owners over the life of a project.

What’s a Digital Twin?

At its most basic level, a digital twin, also known as a digital reality, is a digital version of a physical asset. There’s no limit to what can be twinned digitally, including bridges, equipment, archaeological sites, commercial buildings or an entire city.

After creation, the digital version empowers users to explore an asset and how it might fare in different scenarios, allowing users to learn and test various possibilities without any negative consequences—and without expending any precious budget. These tests allow civil and structural engineers to make real-time adjustments.

While the use of digital twins has expanded recently, creating a twin to test ideas isn’t new. An early (and famous) example of this technology involved the NASA Apollo 13 project in 1970. The team created twins to speed up the development process and manage critical projects. By designing and utilizing a twin on Earth, NASA engineers could test different scenarios before implementing them with astronauts in space—this method helped bring the Apollo 13 crew back to Earth safely following a famous mishap.

One major difference today is that a digital twin can be constantly updated with real-time information from sensors and artificial intelligence. These advancements enable users to better understand the current state of the physical object they’re monitoring, identify potential challenges and model more-efficient operating methods.

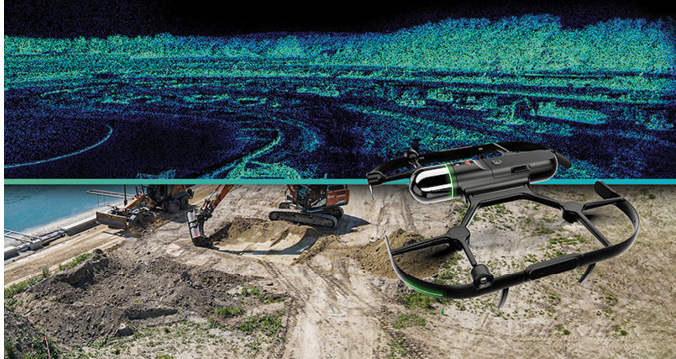

Drones help capture a complete and accurate dataset of a jobsite, which then can be transformed into an actionable 3D data model.

Reality Capture Makes Digital Twins Possible

Survey teams use reality-capture solutions to create detailed digital twins, including laser scanning, mobile mapping and unmanned aerial vehicle (UAV) systems. These solutions can help a single team member quickly capture and analyze spatial data while minimizing safety risks, particularly when gathering data in hard-to-reach places. Further, modern scanners are increasingly detailed; certain scanners can measure the thread of a bolt.

Users can employ 3D laser-scanning solutions to capture data from various platforms while they stand, walk or drive. The captured data then are processed, managed and delivered in the required model, making reality capture efficient and effortless. This enhances efficiency by organizing the workforce and valuable resources, increasing company profits.

Using reality-capture technologies for BIM modeling, verification and as-built documentation is a benchmark for predictive maintenance. It provides a deeper understanding of site limitations and obstacles, and empowers teams to pivot quickly as needed.

Reality-capture scanning tools are powerful and easy to use in multiple applications.

New digital solutions also benefit workforce recruitment and can help all construction industry sectors tackle the persistent labor shortage, covering more ground with fewer people. In addition, these tools attract younger workers while providing training opportunities for current employees, aligning with the trend toward technology-focused jobsites.

How Should Digital Twins Be Employed?

Engineers need visibility into every aspect of a project, an oft-challenging prospect given increasing complexity. Because reality-capture technology is essential for tracking construction progress, quality assurance and documentation, there’s no shortage of assets on the jobsite worthy of a digital twin—from rebar cages to the finished product and every step in between.

Data capture at different stages helps monitor progress against the original design, identify issues early and provide visual documentation for stakeholders. It minimizes errors, monitors construction-site movement and enables informed decision making.

Choosing the appropriate reality-capture technology allows for easy set-ups and transfer of information from field to office.

Unfortunately, some surveyors don’t understand what their clients need. Many surveyors go out and scan and register data, hoping they capture all the needed information. They turn over the details to the client and consider the project finished.

While understanding the deliverables a client expects and needs for a project is critical, people often don’t know what they need until they need it. That works both ways; surveyors should clarify, and engineers must ensure they ask for the proper data.

Projects aren’t created in a vacuum. They develop in a larger environment, and digital twins are particularly useful if problems arise during a construction project. With a digital twin, civil and structural engineers have a historical record they can use to determine the cause of a problem. It could be a bad sub-compaction problem, or the rebar wasn’t properly placed on the deck.

If companies have maintenance issues, they can look at historical information about how a feature was built. Without such data, they’re left to guess the issue’s cause, which can involve time and money to identify—two resources often in short supply.

Can Teams Scan Too Much?

Surveyors often say, “GIS means ‘get it surveyed.’” Every municipality in this country, from big cities to small towns, is developing databases to capture new developments, whether commercial businesses or residential houses. But is there such a thing as capturing too much data? The short answer is no. Companies can always extract the information needed during or at the end of a project. However, they can’t extract information that doesn’t exist.

In addition, teams must consider the potential cost of not scanning an item or location. Not scanning may require them to return to the jobsite, presenting a significant time and budget cost.

Eventually, all data should be tied into a GIS database. Users can always create simple cartesian coordinates with it and upload the data into a GIS database to share it freely with other organizations, contractors and stakeholders.

Is It Easy to Use?

Reality-capture technology provides architects and design teams with increased accuracy at the beginning of a construction or renovation project. This is achieved by creating a complete and accurate dataset of the existing situation or landscape, which then is transformed into an actionable 3D data model.

While reality-capture technology is powerful, it’s also relatively easy to use. A company can take a laborer and show them the scanner’s basic principles. With just basic procedures, companies can teach anyone to scan. Companies can easily train workers to scan locations in the field with just a few quick setups. It doesn’t need to be perfect; just set up a couple targets and start capturing the reality.

All data are starting to go to the cloud. Uploading massive amounts of information takes time and requires storage space, but having the data can pay dividends through time.

One Bite at a Time

Construction companies are always the last to adopt new technology, often complaining that it’s too difficult or expensive. When it first came out, a GPS unit cost $100,000; now it’s on everyone’s phone. Believe it or not, smartphones have some lidar capabilities—not survey-grade, but it’s lidar—and it’s getting less expensive by

the day.

Those who don’t adopt this technology will be left behind. Ultimately, the client will want a digital twin instead of just lines, points and arcs. With a digital twin, they have complete, detailed information about a project.

Capturing site data accurately and completely the first time makes the entire process easier and more cohesive.

If a company is afraid to do the scanning, it can bring in a subcontractor for the job. Alternatively, companies could find a subcontractor they’re comfortable with and consider buying a scanner together.

Contractors don’t always have to build a full reality-capture team; it depends on their needs and how they may evolve. They can perform the fieldwork and partner with someone else to process it.

If starting with a less-expensive scanner, it’s important to remember that the scanner may not have the full range needed. However, starting with a smaller option and working up to a more-advanced scanner allows new users to be comfortable with the tool and understand how it operates.

What’s Next?

The practical uses of scanning locations and capturing data are unlimited. Eventually, every aspect of a jobsite will be scanned; anything that needs to be mapped for any application is a prime candidate.While incorporating digital technology into a project can increase the asset’s lifespan and be a reliable reference point for future maintenance predictions, many potential use cases exist for reality-capture technology; people think outside the box, especially with architecture. Architects are scanning features on buildings, using 3D printers to create specific pieces, and using them to repair or augment buildings.

While digital twins’ potential uses are endless—from virtual tourism to Hollywood—their most-significant benefit is how they can transform the approach to the jobsite and infrastructure.

Since the opportunity is to use technology to make informed decisions based on timely, relevant and local information, teams should scan anything that doesn’t move. There’s no reason not to scan items that may have a potential use—even if that use isn’t immediate. Teams should “scan and can” items, labeling and storing them for later use.

The data captured to create a digital twin of a city enables visualization from all perspectives as well as predictive analytics. Technology helps automate and anticipate the future, identifying potential issues and boosting return on investment.

Most business owners prioritize deploying technology to boost productivity and efficiency, but it’s equally crucial that these operations contribute to a safer jobsite. Construction executives must ensure that every solution they adopt helps eliminate jobsite mishaps and prioritizes the long-term safety of projects and the teams that make them a reality. The ability to capture a complete digital record of projects and structures also gives companies a competitive advantage.

About Troy Dahlin

Troy Dahlin is the vice president for the Heavy Construction Segment of Leica Geosystems, part of Hexagon, in North America; email: troy.dahlin@leica-geosystems.com.