GF Central Plastics Delivers Custom Fabrication Solutions for Commercial Meter Sets

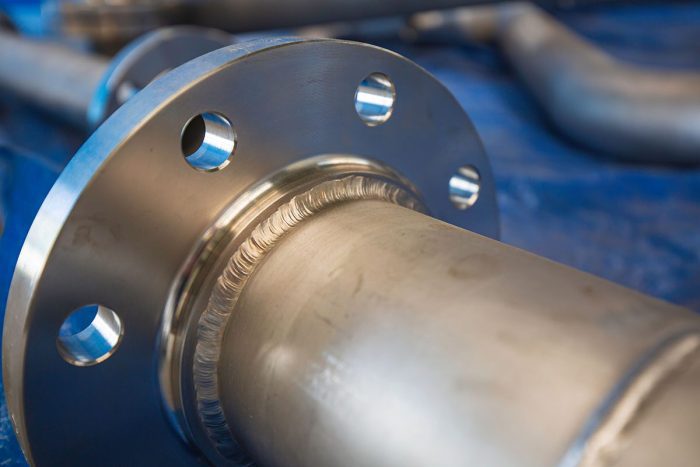

Shawnee, Oklahoma.— GF Central Plastics (GFCP) announces its advanced custom fabrication services for commercial meter sets, showcasing expertise and quality honed over nearly 70 years in the gas utility market. Leveraging In-house Certified Welding Inspectors and API 1104 qualified welders, GFCP delivers tailor-made solutions designed to meet specific customer needs with unmatched precision and reliability.

GFCP’s team of engineers and product managers work closely with clients to address unique challenges from initial briefing through design, manufacture and testing to final delivery. Each meter set is crafted in the U.S.A. with a focus on exceptional quality and performance.

The custom commercial meter sets are engineered for quick installation, significantly reducing on-site labor costs and speeding up project timelines. By minimizing threaded joints, the risk of gas leaks is greatly reduced, enhancing overall safety. Advanced corrosion protection and the designs can be adapted to include support brackets or pipe stands as needed.

Each product undergoes comprehensive quality assurance, including 100% pressure testing to confirm that it is leak-free. The meter sets are constructed using API 1104 certified welding, and custom packaging and shipping options are available to suit individual customer requirements. Traceability is a key feature, with each component marked with heat/lot numbers, rating/grade, serial numbers and material test reports (MTRs). Additionally, a detailed inspection package includes weld mapping, testing, blast profile and paint DFT (dry film thickness) with instrument certification. Products are serialized to meet GIS/compliance needs, with accessible replacement packages provided.

GFCP’s commercial meter sets comply with rigorous industry standards to ensure reliable field performance. They meet the DOT Code of Federal Regulations Title 49 Part 192 and are constructed from materials compliant with ASTM A53/API5L for steel gas carriers. Protective coatings follow SSPC/NACE guidelines, and each part undergoes sandblasting and epoxy/urethane painting to meet specifications, including thickness and color requirements, as well as Cathodic Disbondment Testing, salt spray, and impact resistance testing.

For more information on GF Central Plastics’ custom meter set solutions, visit www.gfcp.com, or contact us toll free at (800) 854-4090 or by email at us.ps@georgfischer.com.

About GF Piping Systems

As the leading flow solutions provider for the safe and sustainable transport of fluids, GF Piping Systems creates connections for life. The division focuses on industry-leading leak-free piping solutions for numerous demanding end-market segments. Its strong focus on customer-centricity and innovation is reflected by its global sales, service, and manufacturing footprint and its award-winning portfolio, including fittings, valves, pipes, automation, fabrication, and jointing technologies.

GF Piping Systems has its own sales companies in 31 countries, which means it is always by its customers’ side. Production sites in 36 locations in America, Europe, and Asia ensure sufficient availability and quick, reliable delivery. In 2022, GF Piping Systems generated sales of CHF 2.16 million and employed 8,085 people. GF Piping Systems is a division of Georg Fischer AG, founded in 1802 and headquartered in Schaffhausen, Switzerland.